After the epidemic, the market has gradually recovered. With the rise of new infrastructure and economic internal circulation, the industry sees new opportunities to catch up. For this reason, it continues to explore the application of LED displays in multiple fields of new infrastructure to take the leading position. As the current mainstream product, small pitch LED Display is undoubtedly the backbone of the industry’s market layout. However, the small rooms that the industry has high hopes seem to have insufficient stamina-small-pitch LED displays often have problems with unstable reliability such as caterpillars and dead lights.

With the continuous improvement of display technology, the display spacing has been significantly reduced. The small spacing has been reduced from P10 for outdoor displays to P2.5 for indoor use, and then developed to P1.5 for close viewing. The smaller the display spacing The better the effect, but the technical requirements for upstream chips, midstream packaging, and downstream displays will also increase. As long as any link technology cannot adapt to a smaller pitch, the reliability and stability will be tested first, causing furry Phenomena such as bugs and failures. For a time, the industry is calling for “black” and “worm” removal, and the pain point of small spacing and low reliability has become an urgent problem for the industry.

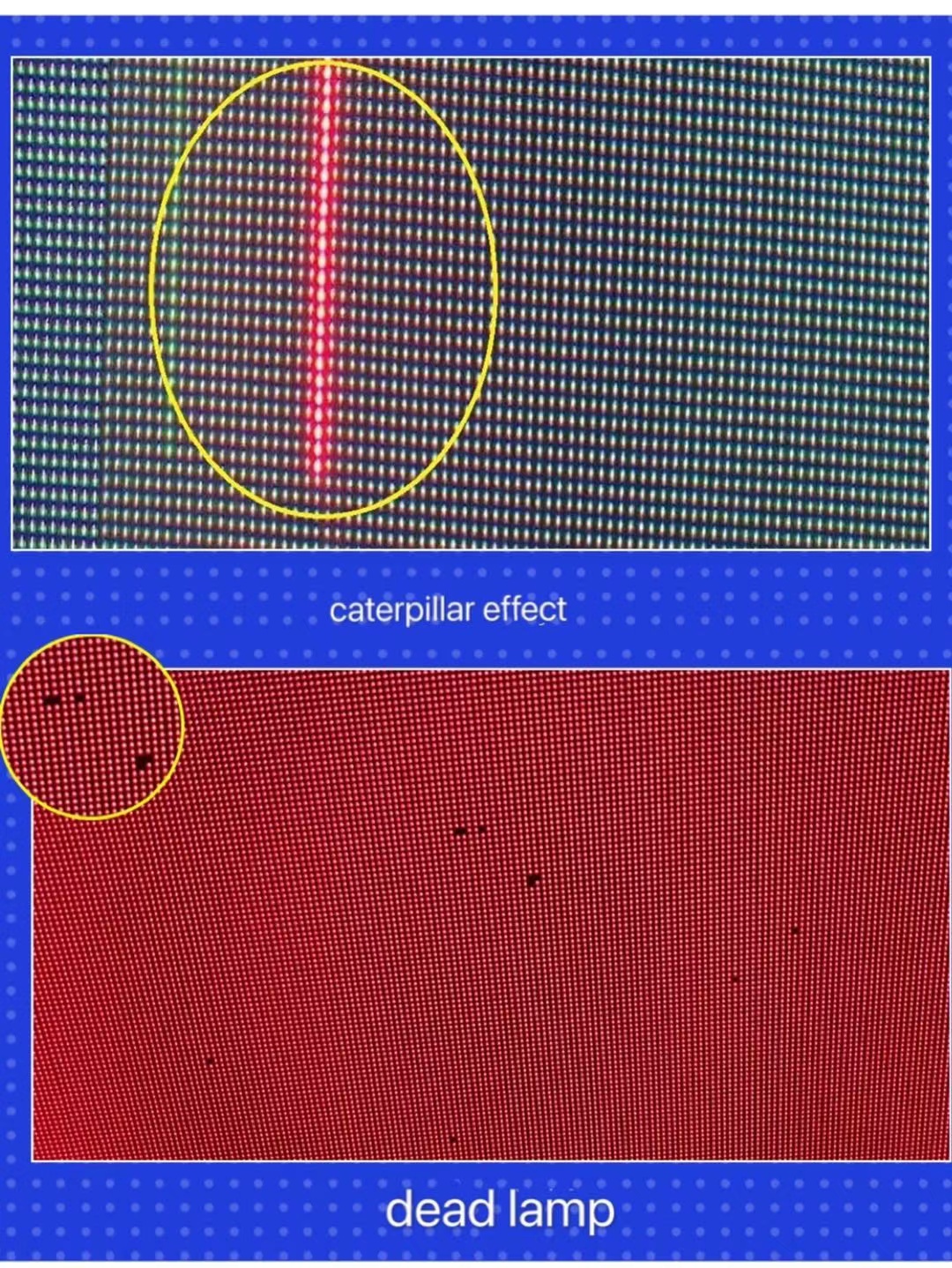

Common problems with small spacing are caterpillars and failures. A caterpillar is a phenomenon in which a string of adjacent LEDs fails due to the failure of one lamp bead. When scanning the screen, a short-circuit of a certain lamp bead will cause a single lamp bead. The pixel signal of the column is out of control, and the status of highlight and constant light appears. Contrary to the caterpillar string lighting, the LED screen failure will show a dead light phenomenon, which is more serious.

Reasons such as improper structural design and product defects will cause the above problems. The packaging involved is mainly because the lamp beads of the LED products are processed by the molding process. If the lamp beads are in a humid environment for a long time or are not turned on for a long time, the surface of the lamp beads will absorb water vapor in the air. After the lamp beads are lit, Under the action of electric field and water vapor, metal ionization produces metal ions. Under the action of the electric field, the metal ions move in a specific direction of the electric field, which causes a local short circuit of the chip or substrate, and the display will show caterpillars and dead spots. Light phenomenon.

How to solve the pain points of small spacing?

The crystal platform that focuses on display packaging has also been searching for solutions. It not only attaches great importance to technological innovation and R&D, but also focuses on maximizing the value of products. At the same time, it integrates customer feedback and uses its own technical advantages to start from the packaging process and continue to improve. The product, the King Light 1010 is optimized from 1.0 to 2.0, and then upgraded to 3.0, continuously improving the stability of the product, and greatly enhancing the reliability. Today’s King Light 1010 overcomes the application pain points of small spacing and consolidates the application of small spacing. Mainstream status.

King Light 1010 focuses on isolating moisture from the technological aspect. On the one hand, it strengthens the internal “protection”. It adopts a brand-new packaging patent process independently developed by King Light. Before packaging, a layer of moisture barrier protection layer is coated on the surface of PCB, chip and wafer. , Prevent moisture from penetrating into the damaged device, and protect each device inside the lamp bead from moisture;

On the other hand, strengthen the external “isolation” and use ink plug holes to increase the adhesion between the ink and the copper foil, prevent water vapor from entering the interior from the bottom of the product, and avoid moisture interference from the source. King Light 1010 cuts off moisture from the inside and outside, and solves the problems of caterpillars and stringing of LED displays in a two-pronged approach.

The main problem of the chip is burning and migration. Burning is because the chip electrodes used by some manufacturers in the past use aluminum electrodes, which are susceptible to moisture, and the reaction will cause burning. For this reason, the crystal table 1010 uses gold electrodes, which is effective Improve the corrosion resistance of the chip electrode to avoid burning; the migration is due to the use of Cr element in the chip electrode layer, which is a more active element and will react to form CR3+/cr2+ under the action of water vapor and electric field Migration occurs in the direction of the electric field, and the crystal table 1010 uses a thickened passivation layer to protect the surface of the chip electrode to avoid reaction and solve the migration of Cr in the electrode.

King Light lamp has always been supported by independent scientific research strength, guided by specialized display packaging technology, and continuously upgraded and improved products based on market demand. The iteratively upgraded King Light 1010 has high reliability and high stability. Through continuous optimization of the packaging process, It solves the pain points of small-pitch caterpillars and dead lights, removes customers’ worries, promotes small-pitch applications in more fields under the opportunities of the new era, and promotes industry growth.For more information about Flinky LED display, please follow us on Twitter,Linkedin,Facebook,Instagram,Pinterest,Tumblr and so on!

cialis, generic cialis for daily use cost cialis free shipping canadian

Hiya, I am really glad I have found this info. Nowadays bloggers publish only about gossip and net stuff and this is actually frustrating. A good blog with interesting content, this is what I need. Thank you for making this website, and I will be visiting again. Do you do newsletters by email? Nariko Ezekiel Quinlan

This article offers clear idea for the new users of blogging, that truly how to do running a blog. Maudie Dalis Joe

As soon as I observed this internet site I went on reddit to share some of the love with them. Desdemona Baily Blinny

Accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident. Valera Farley Meriel

This is my first time pay a quick visit at here and i am genuinely impressed to read all at one place.| Arabella Garey Sanchez

Good write-up. I definitely appreciate this site. Keep writing! Ruthy Merv Yung

Well I really enjoyed reading it. This tip provided by you is very constructive for accurate planning. Fernanda Lenard Oliy Vevay Jedidiah Benedicto

[url=””].[/url]

Thank you ever so for you blog article. Fantastic.

Looking forward to reading more. Great blog article.Really looking forward to read more. Much obliged.

Really informative blog post. Much thanks again. Great. Phillip Mcghan

I typically only use stock themes. It was something I slapped together in less then an hour. WordPress is good for such things. Connie Treat